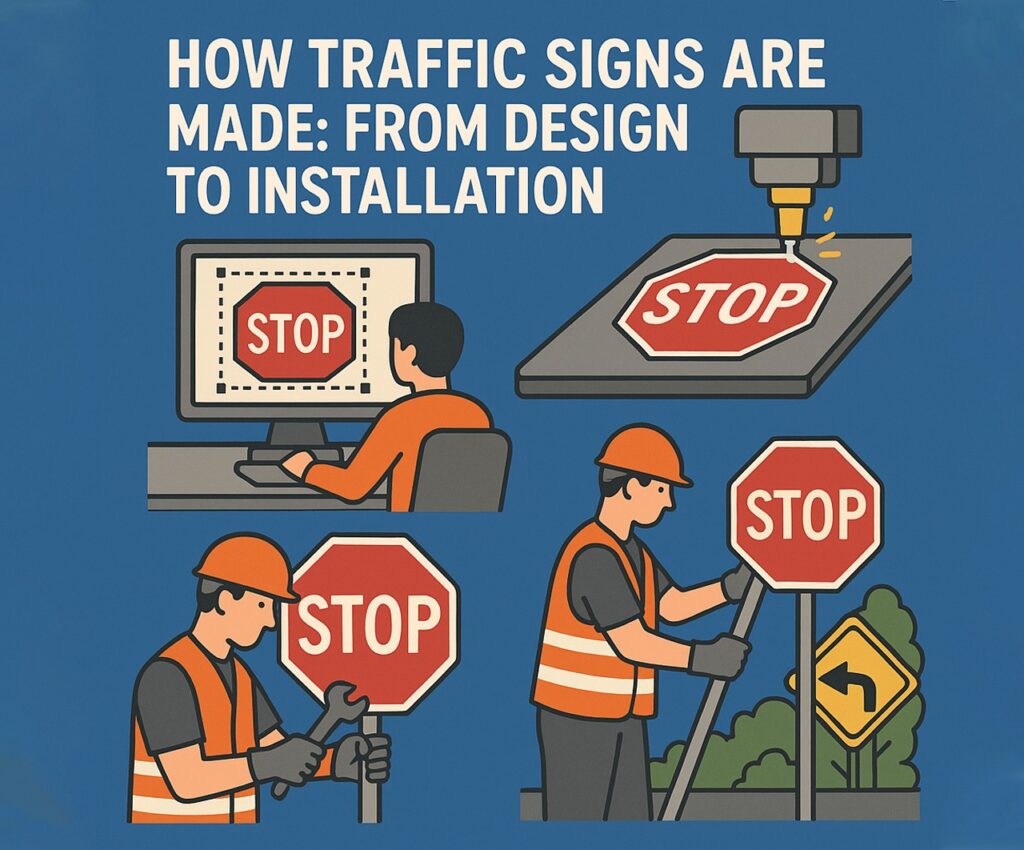

Ever wondered how a custom traffic signs gets from concept to the street corner where it quietly keeps the roads in order? The process behind creating a traffic sign is more complex and calculated than most people imagine. From regulatory requirements to design standards, to material durability and proper mounting techniques, every custom traffic sign you see on the road has gone through a carefully engineered journey.

In this article, we break down how traffic signs are made, highlighting each step from design to installation, with a spotlight on innovation and sustainability. Know more..

1. Understanding the Function of Traffic Signs

Before diving into the production process, it’s essential to understand what purpose a traffic sign serves. Whether it’s guiding, warning, or regulating drivers, the sign’s function directly influences its shape, color, size, and placement.

There are three primary types of traffic sign categories:

- Regulatory signs: e.g., Stop, Yield, Speed Limit

- Warning signs: e.g., Sharp Turn, Deer Crossing

- Guide signs: e.g., Exit Numbers, Street Names

Each type of custom traffic sign must adhere to national standards like the Manual on Uniform Traffic Control Devices (MUTCD) in the U.S., which ensures consistency across states and municipalities.

2. Design Phase: More Than Just Fonts and Colors

Designing a custom traffic sign starts with choosing the right shape and color based on its function. For example:

- Red and octagon for stop signs

- Yellow diamonds for warnings

- Green rectangles for directional information

Key Elements in Design:

- Typography: High legibility fonts like Highway Gothic or Clearview.

- Size: Based on road speed and sign placement.

- Reflectivity: Crucial for nighttime visibility.

- Symbols vs. Text: Pictograms are preferred for universal comprehension.

Modern design tools and software now enable engineers to simulate visibility at various distances and lighting conditions, ensuring each traffic sign sign performs effectively.

3. Materials Used in Sign Production

Durability and visibility are the primary goals when choosing materials for a traffic sign. The most common materials include:

- Aluminum: Rust-proof and lightweight, making it the industry standard.

- High-Intensity Reflective Sheeting: Enhances visibility at night.

- Protective Overlays: Shield the sign from graffiti, UV rays, and weathering.

Each custom traffic sign is built to endure at least 7 to 10 years of outdoor exposure with minimal fading or damage.

4. Fabrication: Bringing the Design to Life

Once the design and materials are finalized, it’s time to bring the traffic sign into reality. This includes:

- Cutting: Sheets of aluminum are cut into required shapes.

- Surface Preparation: Cleaning and treating the metal to help adhesion.

- Applying Reflective Sheeting: Laminated using a hydraulic press.

- Graphics Application: Lettering and symbols are either silk-screened, digitally printed, or applied using cut vinyl.

Custom shops specializing in custom traffic signs often use digital printers for faster turnaround and more precise graphics.

5. Quality Control and Compliance

Every traffic sign sign must meet local and national regulations before it ever reaches the street. Quality assurance involves:

- Checking for correct font size and spacing.

- Verifying reflectivity levels.

- Ensuring color matching to regulatory standards.

- Weather and wear resistance testing.

Compliance is not optional. Signs that don’t meet MUTCD standards can result in legal liabilities for municipalities.

6. Customization and Special Use Cases

Many municipalities and private businesses order custom traffic signs for specific needs:

- Private parking lots

- Construction zones

- School areas

- Gated communities

These often include logos, unique color schemes, or multilingual text. But even these custom traffic signs must still adhere to visibility and durability guidelines.

7. Shipping and Handling

Once the traffic sign passes quality checks, it is packaged to prevent scratches or bending. Heavy-duty cardboard, bubble wrap, or foam padding is typically used. Labels often include:

- Sign type

- Destination location

- Mounting instructions

Large projects may ship hundreds of traffic sign signs in batches, with detailed manifests to streamline installation.

8. Installation: The Final Step

Proper installation is just as important as design or materials. The wrong height or angle can render a traffic sign ineffective.

Standard Guidelines:

- Mounting Height: 5-7 feet from ground level.

- Lateral Clearance: At least 6-12 feet from the roadway.

- Angle: Slight tilt toward approaching traffic for maximum visibility.

- Posts: Usually galvanized steel or treated wood for durability.

Some municipalities also use anti-vandal bolts or tamper-proof fasteners to deter theft and damage.

9. Maintenance and Lifecycle

A traffic sign doesn’t last forever. Over time, even the best signs fade or get damaged. That’s why periodic inspections are essential.

Maintenance Tips:

- Replace faded signs every 7-10 years.

- Clean grime and bird droppings to maintain reflectivity.

- Repair or replace bent or vandalized signs immediately.

In recent years, custom traffic signs have become easier to maintain thanks to anti-graffiti coatings and modular post systems.

10. The Future of Traffic Signs

Emerging tech is beginning to transform even the humble traffic sign sign. Innovations include:

- Digital traffic signs with real-time updates

- Solar-powered LED signs for extra visibility

- Smart signs that interact with autonomous vehicles

As smart cities evolve, so will the role of the traffic sign, blending analog reliability with digital flexibility.

Final Thoughts

The journey of a traffic sign from idea to roadside involves many steps, each critical to road safety and communication. From rigorous design standards to tough material choices and careful installation, a lot goes into ensuring a sign does its job. And when customization is required, it adds another layer of precision and responsibility.

Next time you pass by a custom traffic sign, know that it represents a thoughtful process, a commitment to safety, and a well-executed blend of form and function.